3D Printing

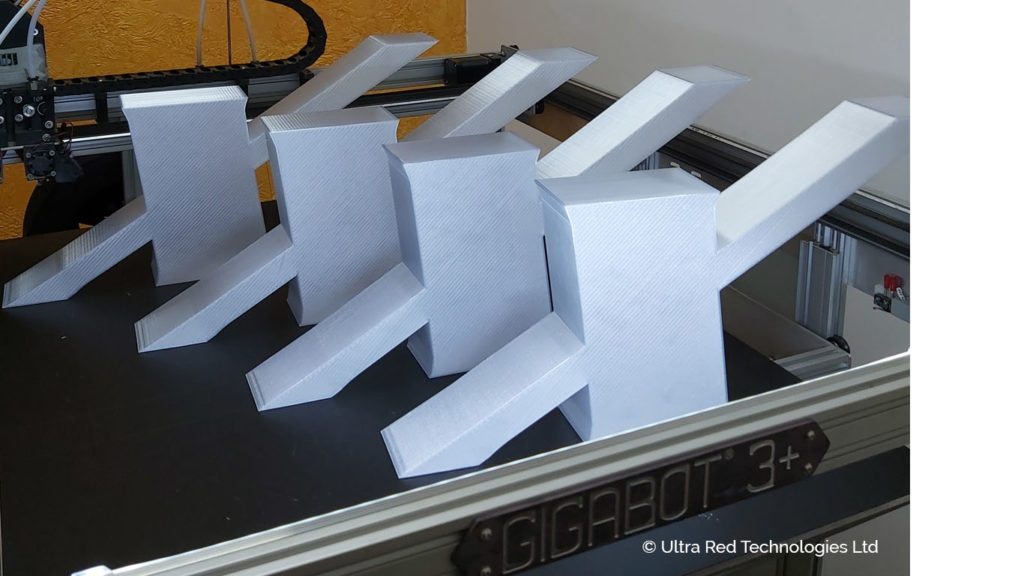

63D printing is a type of additive manufacturing process; to making three dimensional solid objects from a digital file. The technology is now becoming widely adopted all across the world in a variety of different sectors and industries. We at Ultra Red Technologies are the pioneers of 3D printing in Kenya and East Africa. Our fleet of machines allows us to print in large scale and large sizes using our massive FDM printers (having a build volume of 700 x 600 x 900mm). However we can also make extremely intricate parts; using our SLA printing (having a resolution of down to 25 microns or 0.025mm)

3D Printing by Industry

3D Printing has already influenced a large number of industries and is continuing to influence new industries every day. The below are only a few of the industries that have adopted 3D printing to some extent here in East Africa.

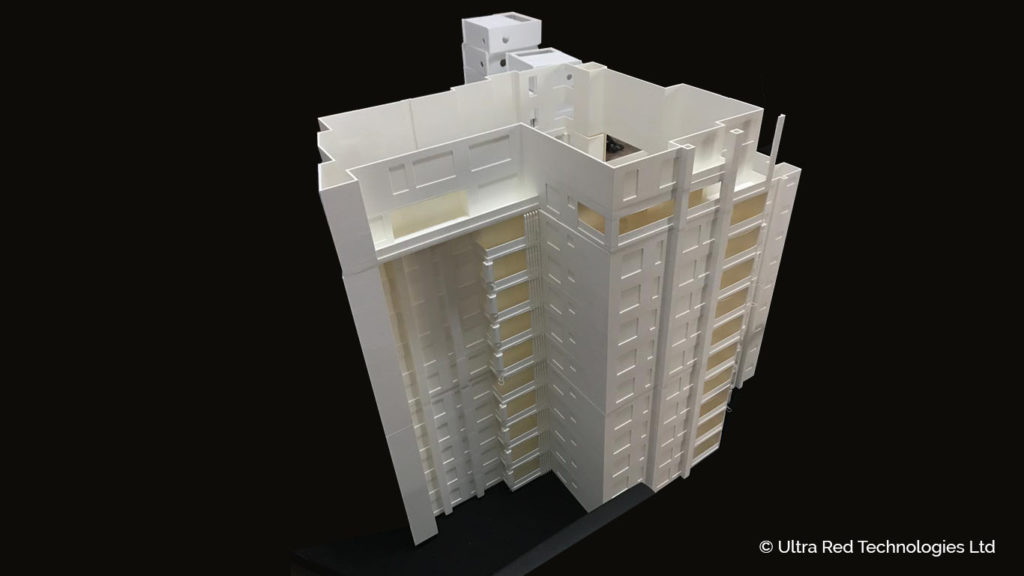

Architecture

3D printing an architectural or construction model gives you the precision of computer design accuracy in a physical object. Furthermore these models are made of plastic, so are very hard-wearing and made to be interacted with.

Medical & Dental

The flexibility of 3D printing offers medical professionals an unparalleled opportunity to create patient specific devices at a affordable cost.

The speed and versatility of 3D printing also provide a major opportunity to innovate during medical emergencies (as seen around the world with the 3D printing communities’ response to the 2020 COVID 19 pandemic).

Major applications of 3D printing in the medical space include:

- Surgical Guides for medical and dental surgeons

- Prosthetics

- Rehabilitation devices

- Dental Implants

- Organs

and the list is ever expanding.

Prototyping

This is the first major opportunity created by 3D printing. Before many innovators realised that there were far more applications for the technology.

Creating prototypes was always a long and expensive procedure. Now with 3D printing; companies are able to make multiple prototype iterations within hours. This allows manufacturers to create more advanced products much faster than before.

Plastic manufacturing has always been a game of high volumes with zero customisation.

With the cost of 3D printing dropping over the last few years; the technology is now able to cater for a new market segment. The ability to create highly customised products at low volumes and a affordable price with no major up-front investment.

3D printing is actually able to compete against injection moulding in many instances. Especially for order quantities below 4000pcs.

Engineering is another major sector in which 3D printing has been able to find a place.

- Spare parts –

- Jigs and Fixtures – These are devices used to speed up and ensure accuracy in assembly plants. Before, the difficulty and expense in making Jigs and Fixtures specifically as aids in assembly plants was extremely high. Now with 3D printing they are so cheap and can be made so easily that they are quickly being implemented even for simple tasks.

- Patterns for metal casting

The advertising industry largely makes one off models or show-pieces. Traditionally this has been through wood, acrylic, metal and a lot of manual effort. Resulting in high costs of production and limited complexity (due to the constraints of the materials).

With 3D printing the most complex shapes and designs can easily be achieved allowing marketers to realise even their wildest ideas.

Even at the cutting edge of the automotive industry 3D printed parts are being made for one off or custom vehicles. Alongside this however the large manufacturers have adopted the use of manufacturing aids that are 3D printed to help with the assembly of cars.

The use of 3D printing in classic car restoration and custom vehicle market is becoming widely adopted around the world. The 3D printed parts are able to replace and even improve on the original factory components.

The jewellery industry has historically been an artisan industry that has relied heavily on manual craftsmanship. This is a time consuming process that would take several days for a highly skilled artisan worker.

Now with 3D printing the same wax model can be printed in a matter of hours; saving lots of time and effort; reducing the total cost of creating unique pieces.

3D printing replaces the manual production of wax models with 3D printed wax-like models directly from a computer design.

Home & Office

With 3D printing there is an opportunity to create low volume highly customised objects.

The technology is also not bound by the constraints of traditional manufacturing methods; allowing highly unique products to be created.

3D printing of Electronic enclosures bridges the gap between prototyping and mass manufacture. It actually allows customers to make small to medium production runs at an affordable cost (up to 4000 units). Without the hassle of large mould costs.